Energy-Efficient Design That Doesn’t Break the Bank: A Conversation

In 2020, the rival Northern Minnesota school districts of Eveleth, Gilbert, and Virginia came together to form Rock Ridge School District. The district worked with Cuningham and two local partner firms, DSGW and ARI, to design three new schools: Laurentian Elementary, Rock Ridge High School, and North Star Elementary.

With a limited portion of the project budget dedicated to energy-efficient design strategies, Cuningham’s design team got creative. The final designs, which feature super-tight building envelopes and simplified mechanical systems, prove that restrictive budgets and high-efficiency designs mustn’t be mutually exclusive.

Here, Cuningham team members Jennifer Garman, Charlie Stoffel, and Rachel Crane discuss their work on the Rock Ridge School District buildings and lessons learned from the project’s unique community context and frugal-yet-impactful regenerative design.

The Team

Charlie Stoffel, AIA, LEED AP - Senior Project Architect: Project Architect for Rock Ridge High School and North Star Elementary.

Rachel Crane, AIA, NCARB – Architect: Designer for Rock Ridge High School and North Star Elementary, worked on construction submittal process for Laurentian Elementary.

Jennifer Garman, AIA, LFA - Architect: Architect for Laurentian Elementary.

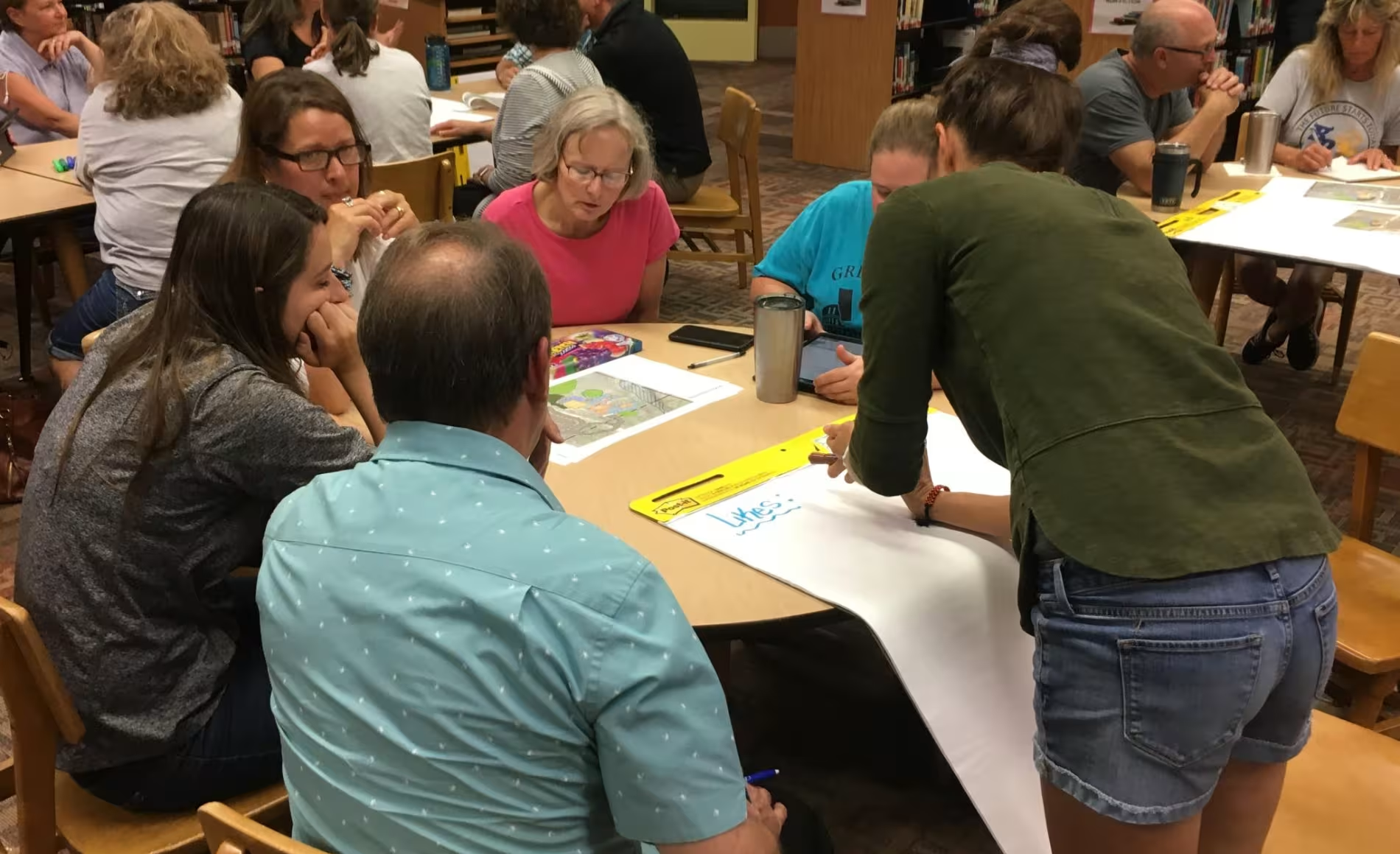

Building on Past Success

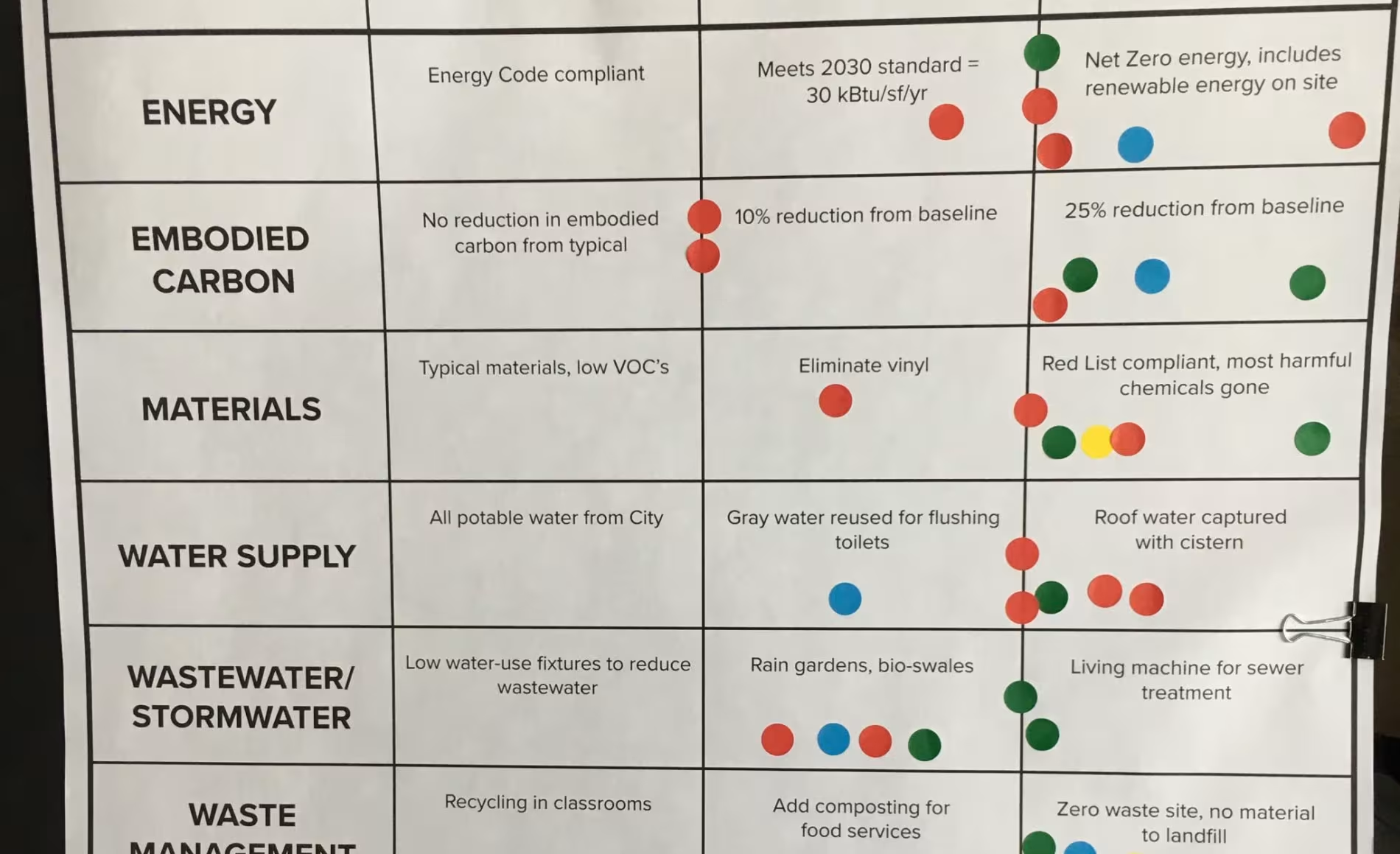

JG: Rock Ridge School District is located on Northern Minnesota’s Iron Range, about three hours north of Minneapolis. The region is Climate Zone 7, which is the same climate zone as Sierra Grande—a high-efficiency school Cuningham recently completed in Colorado. For Rock Ridge, we recreated and re-imagined the sustainability workshops from Sierra Grande, which focused on listening to the community to deduce what specific sustainability goals the project should focus on. We brought the community, teachers, staff, and students together to identify their goals related to a more holistic approach to sustainability.

Ultimately, we were charged with designing the most energy efficient building that the district could afford. One contractor mentioned that typical projects with such a strong sustainability mission have an additional 10% added to the budget. By working within these tight constraints, our approach challenged the perception that high-performing buildings are significantly more expensive than a conventional building.

Embracing the Challenge

JG: Our process really spring boarded from the successes of Sierra Grande, where investing in a high-performing envelope allowed us to reduce the mechanical system sizes and equipment—ultimately offsetting the cost to make it affordable.

The EUI goals that we established for each of the three new schools were as follows:

- Laurentian Elementary: 35 kbtu/sf/yr

- Rock Ridge High School: 46 kbtu/sf/yr

- North Star Elementary : 35 kbtu/sf/yr

For reference, the EUI goals on the elementary schools represented a 53 percent reduction from the Architecture 2030 Challenge baseline (75 kbtu/sf/yr) and a 16 percent improvement on the code minimum (42 kbtu/sf/yr).

Sometimes architects don’t feel empowered to make certain decisions that require owner approval. But how tight we design a building’s envelope is well within our wheelhouse and our purview. So infiltration, which Charlie can speak on more, became one of the biggest focuses of this project.

CS: While there were a fair number of people in the community who were very much in favor of dedicating extra money to creating a sustainable learning environment, there were also a lot of people who weren’t prioritizing regenerative design.

So, as a team, we started to talk about things that were transparent to the general public or the owner that we could do to make this a high performing building without shifting financial resources from other areas. We played with the mechanical systems and insulation levels in the building, as well as focused on air filtration.

JG: Our infiltration goal was significantly tighter than code. Our goal for each of these projects was 0.05 cfm/sf, even though the code is 0.4 cfm/sf. And for Laurentian Elementary and Rock Ridge High School (North Star is still under construction), we well exceeded our goal: achieving 0.036 cfm/sf and 0.022 cfm/sf, respectively.

RC: At Rock Ridge High School, we also had the added benefit of being able to reference our work on Laurentian Elementary, which was a simpler building and further along in the construction process. This allowed us to adjust our details for Rock Ridge prior to bidding so that we didn't have any extra or unexpected cost. In a way, our work on Laurentian became “practice” for our work on the more complicated high school, as they used many of the same materials and techniques.

An Airtight Plan

CS: Once we determined criteria and what the R-values (a measure of how well an insulating material resists heat flow) and the air infiltrations were going to be, our relationship with our consultants became very important. If it wasn’t for the construction manager and mechanical engineer, Kraus Anderson and Obermiller Nelson, really wanting to partner with us, I don't think it would have been possible.

Our construction manager was willing to price for us, at a schematic level, the cost for each of these systems, and we were able to make critical decisions on the approach.

The additional cost associated with a super high-efficiency envelope was offset by the reduced size of mechanical equipment due to lower HVAC loads. The tight envelope will also pay dividends long term as the owner will contribute less in utility expenses starting on day one.

Toward the end of the construction process, our commissioning agent conducted a blower door test—a diagnostic tool to determine how much air is entering from the exterior walls and openings. I was actually on site at Rock Ridge High School during the test. Now these tests are usually pretty uneventful, but on this occasion, you could see in the eyes of the testers that something was not right. Something wasn’t working. The fans they used to test kept shutting off and at one point I worried, “Did we design the building’s envelope too tight?”

As it turned out, the building was so airtight that they had over-estimated the number of fans required for the test. To run the test properly, they actually had to cover more than half the fans because they needed so few to completely de-pressurize the building.

Communication is Key

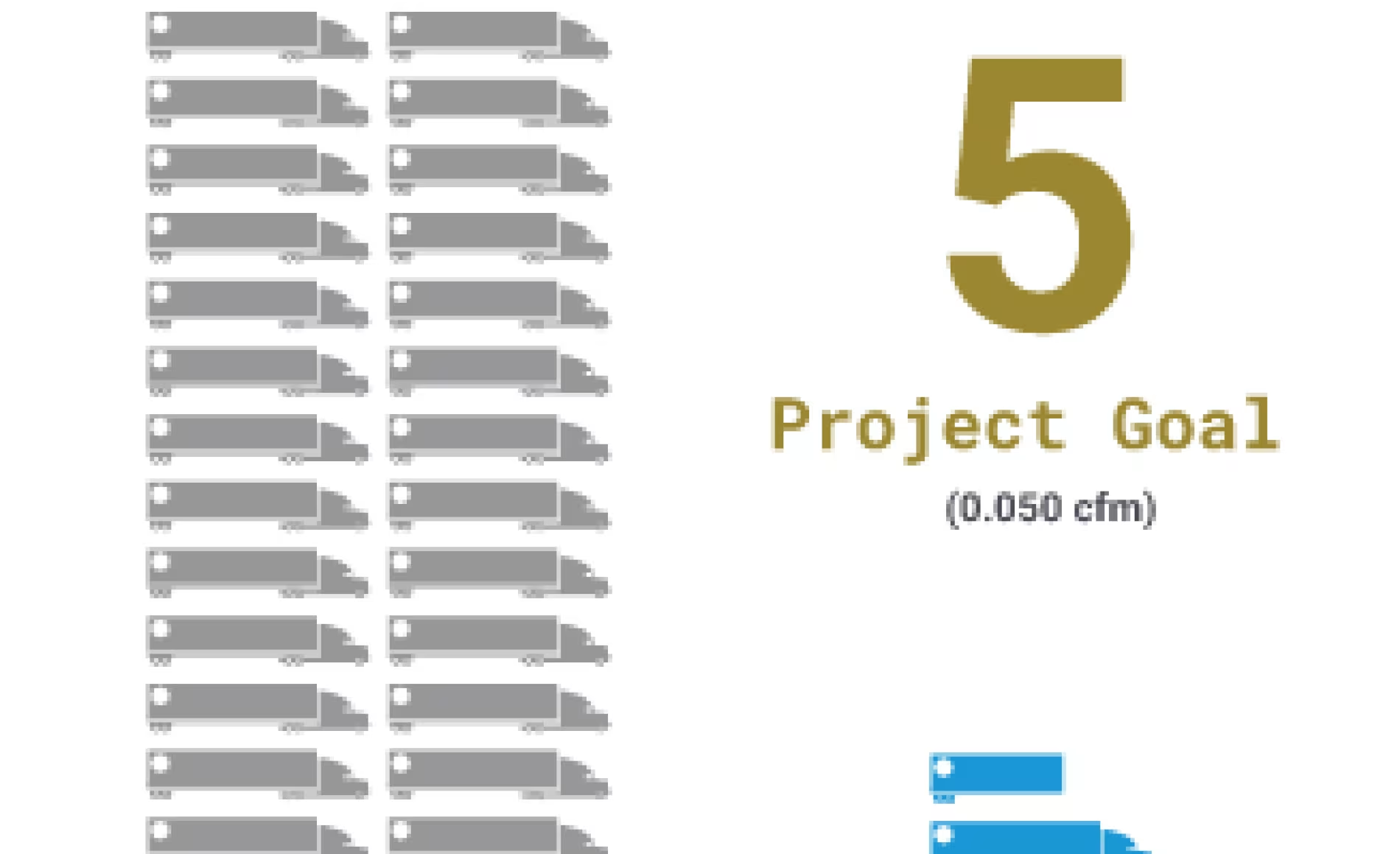

CS: The information we received back from the test was a 30-page document, all in numbers and graphs and things that made sense to only those with a deep understanding of the data. To convert those figures into something tangible that anyone would understand, we decided to use a unique unit of measurement everyone could visualize: semi-trucks.

Think of it like this: the minimum building code allows for 42 semi-trucks full of air to pass into the building every minute. Our stated goal for the project was five trucks. After testing, our final infiltrated air count was only one and a half.

If the building was designed at code minimum, the EUI would be about 55 kbtu/sf/yr. After testing, we determined that EUI was at 45 kbtu/sf/yr. Essentially, we created an 18% increase in efficiency, simply by making the building more airtight.

RC: However, because the building’s envelope was so tight, we anticipated the community may have some questions and concerns. Mainly: if the school is so airtight, won't that lead to sick building syndrome?

To stay ahead of these potential concerns, we worked closely with the district to create an understanding that the low rate of air infiltration means air will not sneak in or out of the building accidentally through cracks or improperly sealed areas—not that the building will lack fresh air. We wanted the school’s users to be confident that the building’s mechanical systems were bringing in fresh air and exhausting old air in a purposeful, thoughtful way. Clear, consistent messaging was critical to achieving that goal.

For me, one of the big lessons gained from this project is an acknowledgment that as designers, it is important to communicate the technical terms we use in a more colloquial way. Not only does this allow the community to better understand the design, but it also gives them the ability to communicate it to others, so they themselves become advocates for regenerative design choices.

Final Thoughts

RC: Ultimately, our work on the three schools is a lesson on the importance of creating the right design and construction team. We were all committed. We had an exceptional energy modeling team, both from Cuningham and our mechanical engineers. We had the envelope consultant and the commissioning agent on board from the beginning, giving us feedback and guidance from the beginning.

Once the contractor manager and sub-consultants realized what this was going to do for the project, they were completely on board with everything we were doing, and it led to great results. And of course, enthusiasm, a sense of humor, and having fun always helps too.

CS: As Rachel said, having the right partners was key. Having a mechanical engineer and construction manager who we could challenge and really engage their creativity made all the difference in the world. Collectively, we found really creative ways to make a positive impact.